Welcome to the offical website of Atekon Automation Technology Co.,Ltd

Solutions

Integrated management and control solution for intelligent pipe corridor monitoring and alarm system

- Categories:Municipal

- Author:

- Origin:

- Time of issue:2020-03-31 11:45

- Views:

(Summary description)With the rapid development of the urban economy, problems such as insufficient scale of integrated pipeline construction and low management level have become prominent. Some cities have successively experienced heavy rains and waterlogging, pipeline leaks and explosions, and road collapses, which have severely affected lives, property safety, and urban operation order.

Integrated management and control solution for intelligent pipe corridor monitoring and alarm system

(Summary description)With the rapid development of the urban economy, problems such as insufficient scale of integrated pipeline construction and low management level have become prominent. Some cities have successively experienced heavy rains and waterlogging, pipeline leaks and explosions, and road collapses, which have severely affected lives, property safety, and urban operation order.

- Categories:Municipal

- Author:

- Origin:

- Time of issue:2020-03-31 11:45

- Views:

Industry background

With the rapid development of the urban economy, problems such as insufficient scale of integrated pipeline construction and low management level have become prominent. Some cities have successively experienced heavy rains and waterlogging, pipeline leaks and explosions, and road collapses, which have severely affected lives, property safety, and urban operation order.

Faced with the current status quo and existing problems, the central government issued the "State Council's Opinions on Strengthening Urban Infrastructure Construction" [Guofa (2013) No. 36] document in due course. Pilot projects for underground comprehensive pipe corridors were launched in 36 large and medium-sized cities across the country. A number of comprehensive pipe corridor projects will be constructed in small and medium-sized cities according to local conditions. Newly constructed roads, new urban areas, and underground pipeline networks in various parks should be developed and constructed in accordance with the comprehensive pipe corridor model.

Guobanfa (2015) No. 61 "Guiding Opinions of the General Office of the State Council on Promoting the Construction of Urban Underground Comprehensive Pipe Corridors" has made overall planning for the construction of pipe corridors. The "Guiding Opinions" pointed out that the pipe corridor supporting system has an intelligent management level to meet the needs of operation and maintenance. It is required to specify the construction requirements of the system in GB50838-2015 "Technical Specifications for Urban Comprehensive Pipe Corridor Engineering".

Brief introduction of urban comprehensive pipe corridor

The integrated pipe corridor is a comprehensive corridor of underground city pipelines. That is to build a tunnel space underground in the city, which integrates various engineering pipelines such as electricity, communications, gas, heating, water supply and drainage. The establishment of a special maintenance port, hoisting port and monitoring system to implement unified planning, unified design, unified construction and management is an important infrastructure and "lifeline" for ensuring urban operation.

Demand analysis

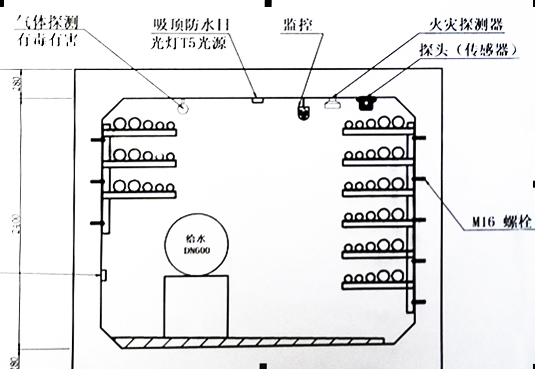

The integrated pipe corridor can be incorporated into urban engineering pipelines for water supply, rainwater, sewage, recycled water, natural gas, heat, electricity, and communications. In accordance with unified planning, design, construction and maintenance, and to meet the requirements of pipeline use and operation and maintenance. The integrated pipe corridor will simultaneously construct firefighting, power supply, lighting, monitoring and alarming, ventilation, drainage, signs and other facilities.

1. System status

The urban integrated pipe corridor monitoring and alarm system relies on multiple systems with different functions, such as environment and equipment monitoring, security precautions, communications, early warning and alarm sub-intelligence, intelligent inspection and management and control integrated information platforms. Or because the products are provided from different manufacturers, there is no unified standard in data exchange. As a result, there are many interfaces and poor accessibility, and it is easy to form individual "information islands":

- The traditional monitoring adopts manual management mode, the operation management cost is high, and the management level and management quality cannot be effectively guaranteed:

- The government's multiple management and decentralized operations are prone to various problems. Solve each other's suspicion and bluff when an emergency occurs.

- It is difficult to improve the operation and maintenance monitoring and monitoring capabilities, emergency dispatching and commanding capabilities, and comprehensive business capabilities of municipal facility management.

- There are different types of surveillance video and surveillance data in the corridor, and the information islands between the various systems make it difficult for relevant departments to make decisions.

2. Monitoring requirements

The design of the comprehensive monitoring and alarm system of the pipe corridor includes the environment and design monitoring subsystem, ventilation subsystem, power supply subsystem, lighting subsystem, drainage subsystem, security prevention subsystem, voice communication subsystem, early warning and alarm subsystem, intelligence Robot inspection system, integrated management information platform subsystem, etc. According to the technical requirements of "GB50838-2015 Urban Combined Pipe Corridor Engineering Technical Specifications", the comprehensive monitoring and management system of the pipe corridor should include the following design:

(1) 200m is designed as a fire compartment, with firewalls and fire doors.

- Each zone is designed with a monitoring and alarm system for environmental parameters such as temperature, humidity, water level, oxygen, hydrogen sulfide and methane.

- Design an electronic patrol management system for each zone.

- Each district design a set of fixed communication and wireless intercom system.

- Fire extinguishing equipment is set along each line and an automatic fire extinguishing system is configured.

- Each zone is equipped with mechanical ventilation, using three methods: local manual, local automatic and remote control.

(2) One discharge port, natural air inlet (with personnel entrance and exit) in each zone, and 800m design section maintenance port (with personnel entrance and exit).

- Fire extinguishing equipment shall be installed at the discharge port, maintenance port, personnel entrance and exit.

- Set the camera at the discharge port, maintenance port, personnel entrance and exit.

- Discharge ports, maintenance ports, personnel entrances and exits are equipped with entrance and exit control devices, intrusion alarm detection devices, and audible and visual alarms.

(3) Set a sump in each zone.

- Set online water level monitoring.

- Design automatic drainage device for water pump.

(4) Pipeline exit hatches are set at 200m and intersections.

- Fire extinguishing equipment shall be provided at the location where the pipeline exits the hatch.

- Set the camera at the position where the pipeline exits the hatch.

- The entrance and exit of the pipeline is equipped with entrance and exit control devices, intrusion alarm detection devices and sound and light alarms. Technical solutions

Technical solutions

1. Program Overview

The integrated pipe corridor monitoring and alarm system is a very comprehensive management and control system. Due to the different technical systems and the different standards adopted between the various systems, it is difficult to be compatible and interoperable. This not only needs to take into account the needs of environment and equipment monitoring, communication, information management, etc., but also needs to take into account the need for image monitoring in disaster early warning, security and other aspects. At the same time, it is also necessary to consider the integration of supporting systems such as alarm and access control and linkage with the broadcasting system. Therefore, in the interconnection process of these systems, the problem of heterogeneous information islands will inevitably occur.

To break the situation of information islands, the monitoring and alarm system of complex and heterogeneous methods needs to solve the problems of compatibility between different manufacturers and different products and the integration of multiple systems. Need to consider the platform's network access and resource development methods. It also needs to be designed from the perspective of large-scale network users, and grasp the principles of mutual benefit and sharing.

"Integrated platform for management and control of urban comprehensive pipe corridor monitoring and alarm system" developed by Nanda Automation Technology Co., Ltd. It is based on the integrated technology of management and control, which successfully solves the problems of compatibility of many brands, integration and integration of various systems, and inconsistency of protocols and interface standards. It becomes the future development direction of the integrated pipe corridor monitoring and control system. According to the background of the comprehensive pipe corridor industry and the current requirements for on-site management and control applications, the concepts and technologies of information-based and intelligent “Industry 4.0”, “Internet of Things” and “Smart City” are fully considered. And combined with the years of experience of the management and control integrated platform developed by Nanda Auto in the power, rail transit, coal mine, chemical industry, etc., this solution is proposed.

2. Design principles

According to the user's current situation and needs analysis, the integrated pipe corridor monitoring and alarm system platform is designed according to the following principles:

(1) Reliability

The system should ensure the reliability of the data acquisition, fusion and transmission of the pipe corridor. Among them, perceptual data is the basis and judgment basis of various applications of the pipe corridor, and reliable data acquisition, fusion and transmission are the basis for ensuring the normal operation of the pipe corridor function.

(2) Scalability

The system should be able to dynamically adjust to provide scalability for different network applications, including scalable network topology and scalable service content. The flexible expansion of the network is to meet the access of the pipeline corridors developed in different periods, leaving design space and standardized interface methods. The service content can be expanded to meet the different needs of the service side, leaving an open network interface for remote meter reading, street lamp intelligent management and other systems that may be accessed later.

(3) Compatibility, openness and easy maintenance

The software and hardware of the system adopt modularization and configuration design, which can easily expand the capacity and maintain and upgrade the functions. At the same time, the system construction is based on Web, C/S structure, and the software is set with an open network interface, which can realize the uploading of monitoring information to the monitoring center and competent departments and units at all levels.

(4) Security

The security standards of the monitoring and alarm system should specifically protect the user's information privacy and provide network applications with different security levels for various government departments and units.

3. Design ideas

(1) From a safety perspective

At present, the following four major problems exist in the integrated pipe corridor:

One is the personnel safety problem caused by human unsafe behavior (violation). The second is the equipment safety problem caused by the unsafe state (hidden danger) of things. The third is the environmental safety problems induced by environmental unsafe conditions (hidden dangers). The fourth is the security issues of the corridor caused by the insecurity of the organization (management loopholes).

The above four core factors jointly induce the abnormal transmission of energy, resulting in an accident in the pipe corridor. Therefore, the system must manage and control these four core factors in order to realize rapid, flexible, and correct understanding and resolution of unsafe behaviors of people, unsafe states of things, and unsafe factors of the environment. In order to achieve the intrinsic safety of the underground pipe gallery.

For the safety of personnel: through personnel positioning, access control systems, portable inspection instruments, personnel detection counters and other unsafe behaviors of control people, the inspection personnel can achieve visual management, and unrelated personnel can achieve intrusion prevention management. And can use the intelligent robot inspection system to complete some tasks of the current manual inspection, which can ensure the safety of personnel.

For environmental safety: Real-time monitoring of temperature, humidity, water level, oxygen, H2S, CH4 and other environmental elements of the pipe corridor through multi-functional monitoring base stations and smart sensors to realize the management, identification, assessment and control of hazard sources, thereby eliminating environmental unsafe factors .

For device safety:Real-time online sensing, alarm linkage, remote control and command and dispatch of monitoring equipment, drainage equipment, ventilation equipment, communication equipment, fire fighting equipment, lighting equipment, cable temperature, etc. through intelligent sensors, meters and multi-functional monitoring base stations, so that they are always in safe state.

For management security:Through the establishment of safety mechanisms and early warning management systems, on-site visualization, problem visualization and hidden hazards visualization can be achieved to achieve no errors in management, no errors in command, and no errors in operation.

The construction goals of the urban comprehensive pipe corridor:On the basis of information management, gradually realize automation, cover the entire process of the operation and management of the entire pipe corridor with wisdom, and realize an efficient, energy-saving, safe, and environmentally friendly "management, control, operation" integrated intelligent pipe corridor.

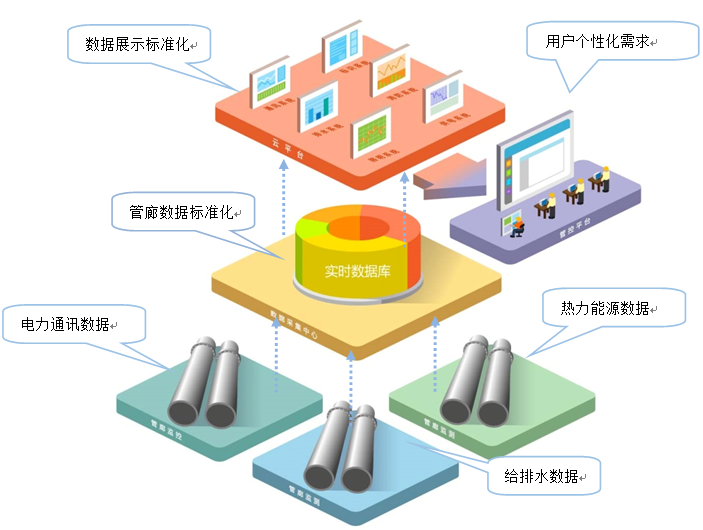

(2) From the perspective of the Internet of Things

This system uses advanced Internet of Things technology, through a four-layer architecture of sense, transmission, knowledge, and use, to achieve a thorough perception and measurement of the attribute information and status information of the underground pipe gallery. By real-time access to all data including personnel, equipment, environment, process systems, etc., to achieve visualization of underground pipe corridor management, improve pipe corridor safety and user satisfaction.

As can be seen from the above figure, all the information in the pipe corridor must be transmitted to the platform monitoring center through the standardization of equipment data, and various control commands of the monitoring center must be transmitted to various devices in each section of pipe corridor.

This information mainly includes:

- Analog data of environmental sensors and equipment sensors.

- Personnel location information and personnel alarm information.

- Monitor the video signal and control signal of the camera.

- Fan, water pump and other equipment status information.

- Voice information and wireless intercom information of IP phones.

- Various attribute information and status information of the pipe corridor.

- Management instructions and process information.

We use an integrated solution based on management and control integration to resolve all of the above problems. The system is based on the standard interface of the Internet of Things, and users can smoothly process data from different devices and environments to meet the expansion needs of end devices.

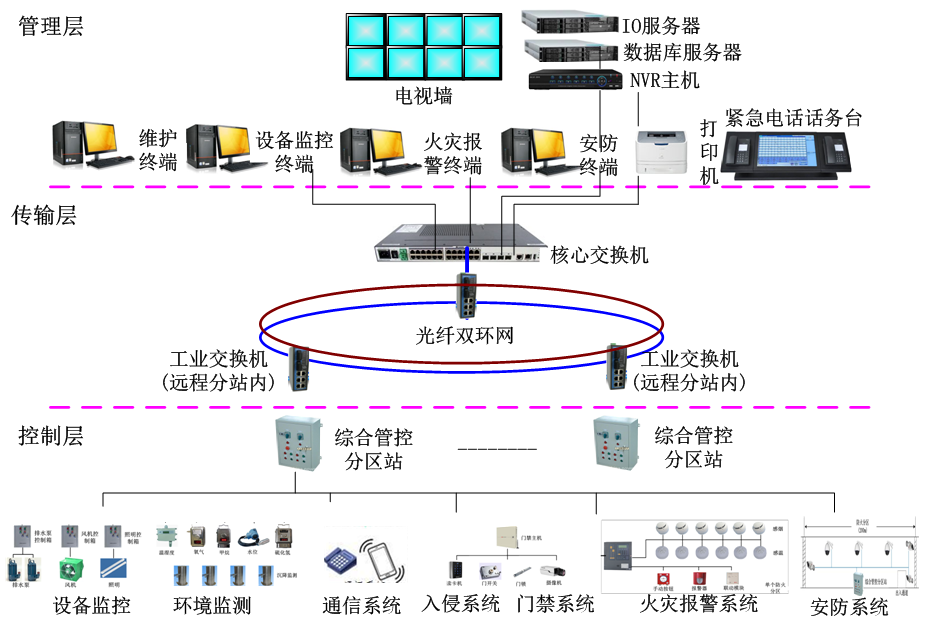

4. System flow design

According to the complex situation and characteristics of the operation of the integrated pipe corridor, the establishment of a monitoring system based on an integrated management and control platform is the only way to achieve a smart pipe corridor. The comprehensive pipe corridor must realize the safe and stable operation of the system, as well as the "centralized management" of the power supply, fire fighting, lighting, ventilation, drainage and other systems.

- Perception layer:Perceive various data from power, water supply, communication, energy and other systems.

- Transport layer:The multi-functional base station of the Internet of Things provides reliable transmission such as wireless and wired communication.

- Processing layer:Through a "uniform management information platform" integrated environment and equipment monitoring system, security system, communication system, early warning and alarm system, management and control platform system five central modules to achieve distributed application and vertical penetration of the system.

- Application layer:Since the professional pipeline operation information of the government management department and the four major pipeline units (water, electricity, gas and communications) will affect the safety of the pipeline corridor or other professional pipelines, the four major pipeline units should be provided at the application layer. Communication interface to achieve information sharing and linkage.

System composition

The integrated pipe corridor monitoring and alarm system is a deeply integrated automation platform. It integrates subsystems such as equipment and environmental monitoring, video monitoring, security, fire alarm, voice communication, power monitoring, intelligent robot inspection and information management platform. Through the integration and interconnection of the automation system in the corridor, it provides a complete and unified monitoring and management platform for operation and maintenance personnel.

The integrated pipe corridor monitoring system is divided into three layers and six systems. The third layer consists of the management layer, the network transmission layer and the field acquisition control layer. The management layer is the core of the entire monitoring system. It connects, coordinates, controls and manages the work of each subsystem. The transmission layer includes the network between Mingdaokou and the monitoring center through optical fiber transmission, to achieve the communication of video data, audio data, TCP/IP control data and RS-485 data. The on-site detection and control layer is mainly composed of access layer switches, network cameras, and on-site area controller PLC. Among them, the PLC is responsible for collecting the detection signals in the pipe corridor, logical operation analysis and automatic and manual control of the equipment in the pipe corridor according to the signals. The five systems include an environment and equipment monitoring system, a security system, a communication system, an early warning and alarm system, an intelligent robot inspection system, and a unified management information platform. The system block diagram is shown below:

The system establishes an integrated intelligent management and control system based on the "management, control and operation" of the Internet of Things. The design of the system from the aspects of data collection, communication network, system architecture, intelligent linkage and integrated data service solves the fundamental problems of strong internal interference, many users and complicated coordination in the construction of pipe corridor monitoring and alarm. Greatly improve the reliability and manageability of the system operation, improve the recovery efficiency of the pipeline corridor infrastructure, environment and equipment, and then realize the monitoring center application "one platform, three-tier structure, six systems". That is, the remote management and linkage control of the equipment in the pipe corridor can be performed.

Scan the QR code to read on your phone

底部二维码

Welcome to Atekon

Technology official Wechat

底部联系方式

Address: Floor8,BuildingD,Cloud Security City,No.19 Ning shuang Road,Yuhuatai District,Nanjing

Production Center: No. 219 Qingshuiting West Road, Jiangning District, Nanjing City

Telephone: 025-68530188 (Switchboard)

Fax: 025-68530178

Service Hotline: 400-025-0150

Technical support: 025-68530179

底部备案号

Atekon Technology Co.,Ltd Record number: 苏ICP备09042342号-1