Welcome to the offical website of Atekon Automation Technology Co.,Ltd

Solutions

Application of NA2000 PLC in rural sewage treatment

- Categories:Water treatment industry

- Author:

- Origin:

- Time of issue:2020-05-18 10:08

- Views:

(Summary description)

Application of NA2000 PLC in rural sewage treatment

(Summary description)

- Categories:Water treatment industry

- Author:

- Origin:

- Time of issue:2020-05-18 10:08

- Views:

The vast majority of rural sewage in my country is directly discharged into water bodies without treatment. Rural domestic sewage accounts for a large proportion of the sources of lake pollution in my country. With the increasing level of urbanization, rural urbanization and urban-rural integration in my country, and the improvement of farmers' living standards, the discharge of domestic sewage in towns and villages will continue to grow rapidly. This will undoubtedly bring more pressure on water source protection. In order to protect urban water sources and gradually improve the quality of the water environment, it is necessary to increase sewage treatment. In order to effectively promote the construction of a new socialist countryside, improve the rural environment in an all-round way, and effectively solve the outstanding problems of the current rural garbage garbage, rural sewage sewage disposal, and lagging governance, accelerate the construction of a new socialist countryside and further improve the rural area Production and living conditions of the masses. The quality of the rural ecological environment must be continuously improved. Therefore, the treatment of small domestic sewage in towns and villages is particularly important.

Rural sewage has the following characteristics:

(1) The sources of pollution are relatively dispersed, the amount of water is small, the concentration of organic matter is high, and the coefficient of daily change is high.

(2) Most rural areas are relatively backward in economy and cannot afford high-input processing facilities, while land resources are relatively abundant.

(3) Lack of corresponding professional management personnel.

Existing technologies mainly use biological methods for domestic sewage treatment: A2O, oxidation ditch and other activated sludge methods commonly used in urban sewage treatment plants. The characteristics of these methods are: the sewage pipe network is required to collect the sewage, the operation of the structure is complicated, the construction and operation cost are high, and the management of professionals is required. Therefore, these methods are difficult to apply to the treatment of rural scattered domestic sewage.

Project Overview

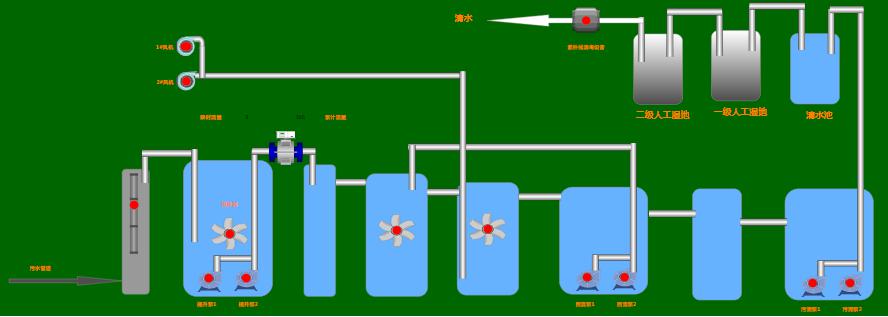

The sewage treatment project of XX Village, XX City, Shanxi Province is a daily sewage treatment capacity of 150T. It passes through various treatment steps such as grille pool (separating floating matter in sewage), regulating tank, anaerobic tank, pre-out-of-stock tank, anoxic tank, aerobic tank The clean water after treatment and separation will be discharged to the constructed wetland, and then ultraviolet disinfection will eventually reach the discharge standard and be discharged to the river.

Project implementation plan

- One mechanical grill is used to control the separation of floating matter and sewage in sewage.

- Sewage flows into the regulating tank through pipeline self-flow, and is sent to the anaerobic tank through the lift pump, and the flow data is monitored.

- It flows to the pre-out-of-stock pool, anoxic pool, and aerobic pool in a self-flowing way.

- The reflux pump in the aerobic tank will transport the sewage to the pre-out-of-stock tank, and the supernatant will flow to the sedimentation tank and sludge tank.

- The supernatant in the sludge tank flows to the clear water tank and the first and second artificial wetlands, and the sludge is discharged through the sludge pump.

- The supernatant is further processed in the constructed wetland and discharged to the river after reaching the discharge standard through ultraviolet disinfection equipment.

- All devices must implement local and remote (touch screen and cloud) control functions.

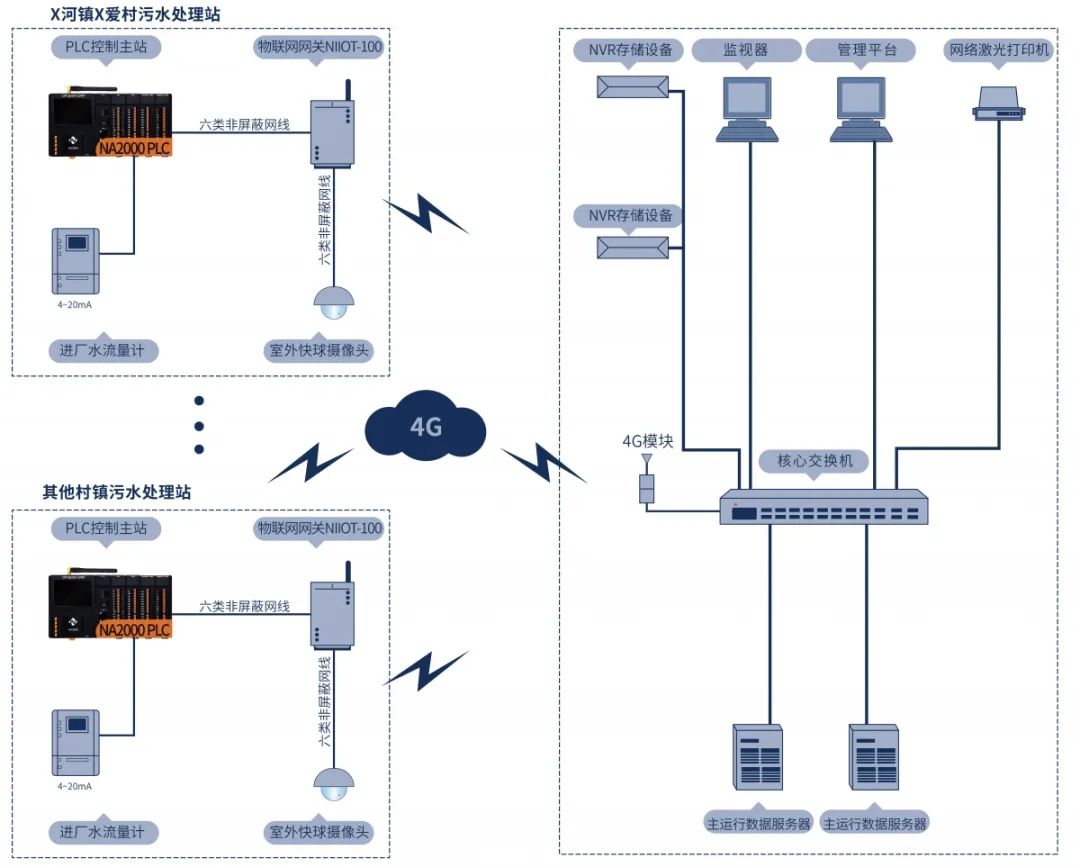

整体网络图(来自设计图纸)

The project uses a third-party cloud platform for drawing design, and only uses NA2000 PLC and touch screen as the control center to achieve on-site control functions. Later projects of this type can be recommended to use Aoto Cloud and NAControl to achieve remote monitoring and management for easy maintenance. In addition, an environmental protection equipment manufacturer in Shaanxi has implemented 30 sets of sewage equipment connected to Aoto Cloud for monitoring.

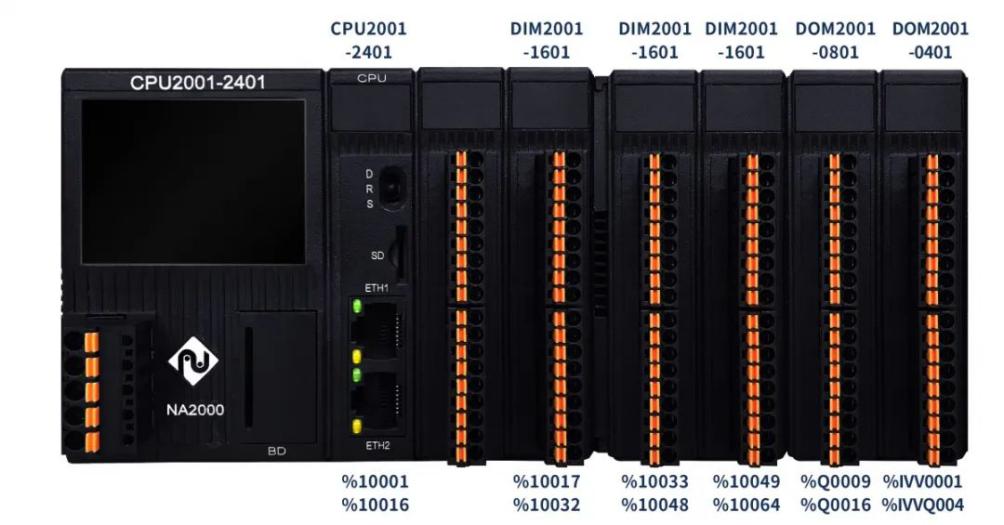

According to the NA2000 PLC IO points configuration as shown below:

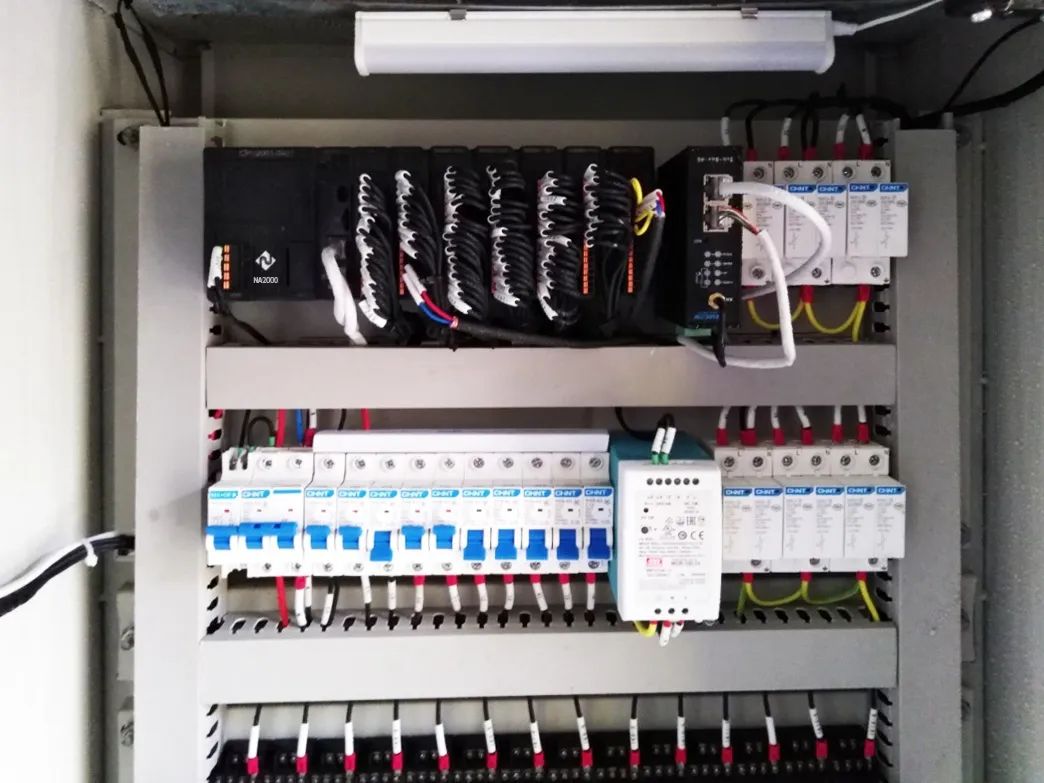

The installation diagram in the implementation cabinet is as follows:

The cloud picture is as follows:

Process drawing (from third-party cloud)

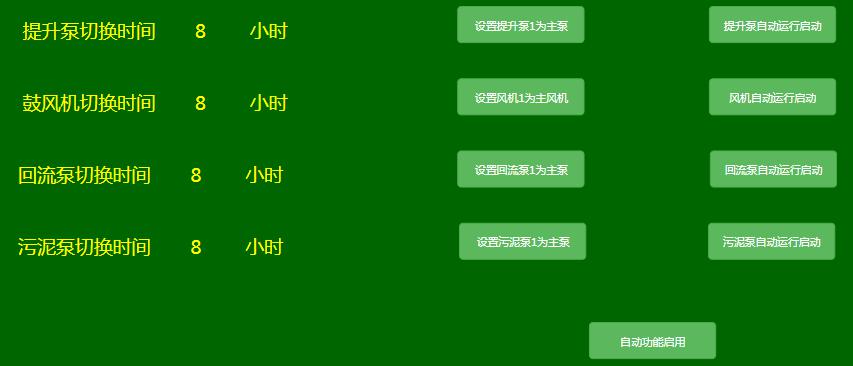

Setting screen (from third-party cloud)

Manual screen (from third-party cloud)

Project summary

Rural sewage treatment stations are more scattered. Through the PLC integrated control system and the 4G wireless transmission method, not only can the real-time monitoring and management of the sewage station be realized in the central control room, but also the upper computer can be used to remotely program, modify and debug the procedures of each sewage station in the management center. At the same time, each station can avoid laying optical fiber to the management center, liberating a lot of manpower and material resources and saving social resources.

Application development

With the economic development, wireless 4G applications will become more and more widespread. Especially in industrial and civil applications, NA2000 series PLC integrates wireless and field control in one. It replaces the PLC and wireless communication module solution, which is convenient for on-site configuration, and can be realized by a set of software, avoiding multi-software and multi-link operation, and reducing the fault points for operation and debugging. The following describes several applicable occasions:

1. The equipment or project site has 4G network, and the distance for laying lines is long. In order to reduce costs, CPU+4G can be used to realize control and monitoring. The structure diagram is as follows:

2. When there is no 4G network on the equipment site, and the distance is relatively long, and the conditions for laying cables are not available, CPU+wireless bridge (such as Tengyuan Zhituo) can be used to transmit to the cloud through MQTT. The specific structure diagram is as follows:

不同网桥传输距离不同

Scan the QR code to read on your phone

底部二维码

Welcome to Atekon

Technology official Wechat

底部联系方式

Address: Floor8,BuildingD,Cloud Security City,No.19 Ning shuang Road,Yuhuatai District,Nanjing

Production Center: No. 219 Qingshuiting West Road, Jiangning District, Nanjing City

Telephone: 025-68530188 (Switchboard)

Fax: 025-68530178

Service Hotline: 400-025-0150

Technical support: 025-68530179

底部备案号

Atekon Technology Co.,Ltd Record number: 苏ICP备09042342号-1