Welcome to the offical website of Atekon Automation Technology Co.,Ltd

Solutions

Regional Control Unit ACU of Underground Comprehensive Pipe Gallery

- Categories:Comprehensive pipe corridor industry

- Author:

- Origin:

- Time of issue:2020-05-18 11:57

- Views:

(Summary description)The function of the environment and equipment monitoring system is to realize the whole process of monitoring the parameters and status of the environment and equipment in the whole area of the comprehensive pipe corridor. The real-time monitoring information is accurately and timely transmitted to the unified management information platform of the monitoring center through the multi-functional comprehensive management and control partition station.

Regional Control Unit ACU of Underground Comprehensive Pipe Gallery

(Summary description)The function of the environment and equipment monitoring system is to realize the whole process of monitoring the parameters and status of the environment and equipment in the whole area of the comprehensive pipe corridor. The real-time monitoring information is accurately and timely transmitted to the unified management information platform of the monitoring center through the multi-functional comprehensive management and control partition station.

- Categories:Comprehensive pipe corridor industry

- Author:

- Origin:

- Time of issue:2020-05-18 11:57

- Views:

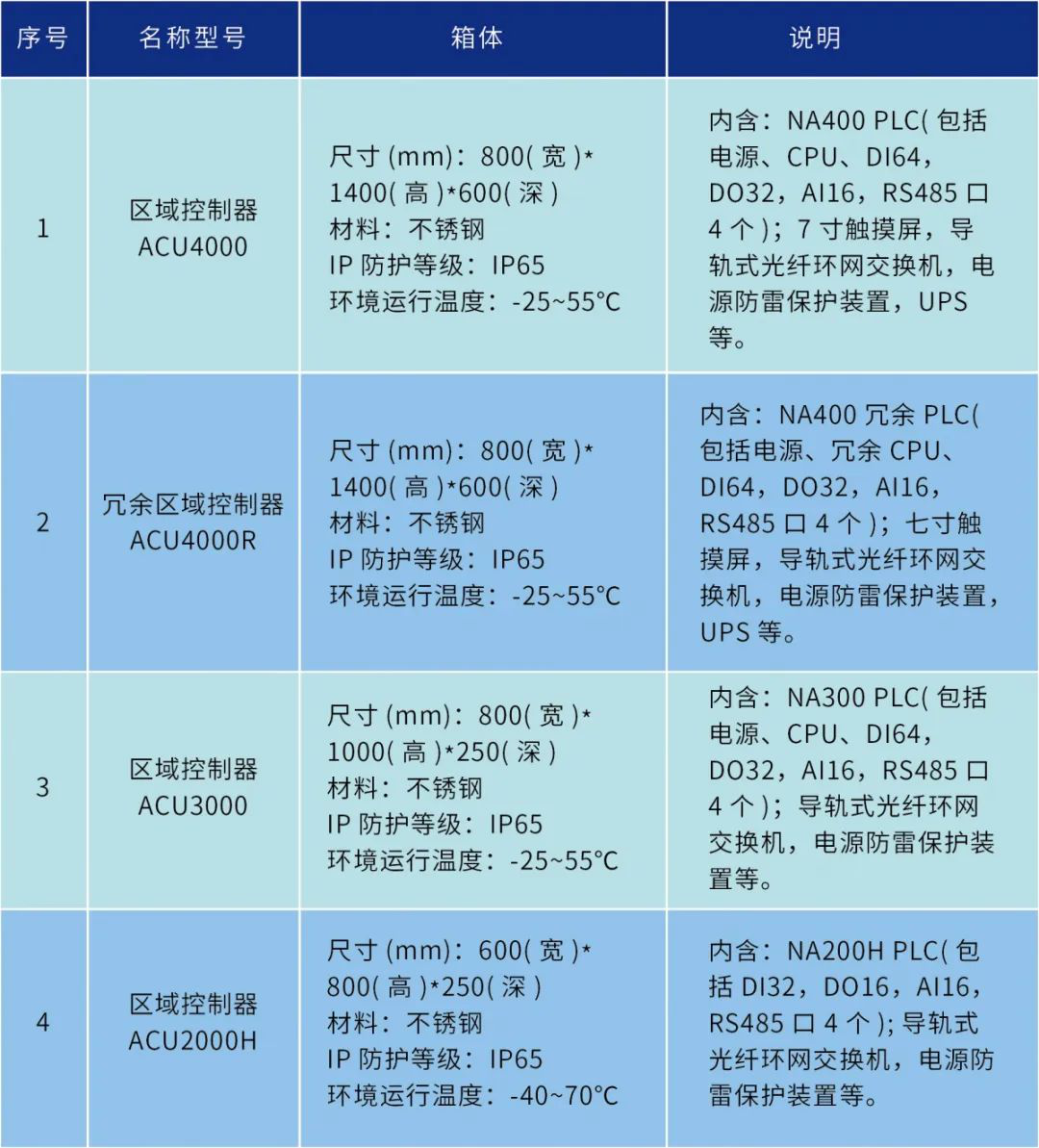

The function of the environment and equipment monitoring system is to realize the whole process of monitoring the parameters and status of the environment and equipment in the whole area of the comprehensive pipe corridor. It transmits real-time monitoring information to the unified management information platform of the monitoring center accurately and in a timely manner through the multi-functional integrated management and control station. It is convenient for the on-duty personnel to discover the on-site environment and equipment problems in a timely manner, eliminate faults and deal with the alarm situation in a timely manner to ensure the normal operation of the pipe corridor. The pipe corridor environment and equipment monitoring system are generally equipped with an ACU area controller every 200 meters. The PLC controller independently developed by Nanda Automation Technology Co., Ltd. has developed a variety of professional regional controllers for the pipe corridor.

Features

Environmental monitoring >>>

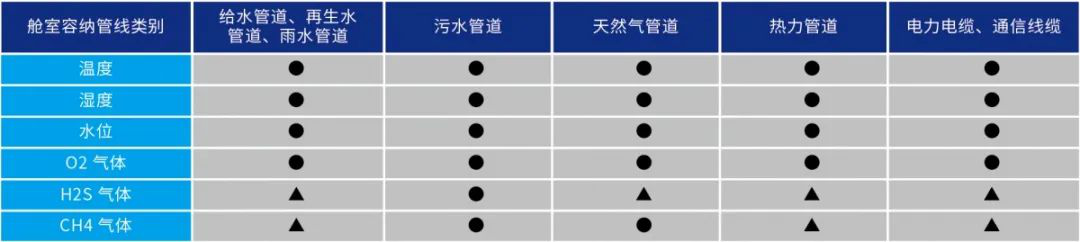

The environment and equipment monitoring subsystem detects and alarms the environment parameters in the pipe corridor. The content of environmental parameter detection is as follows. The setting of the gas alarm value complies with the relevant provisions of the national standard GBZ/T205 "Code for the Protection of Occupational Hazards in Confined Space Operations".

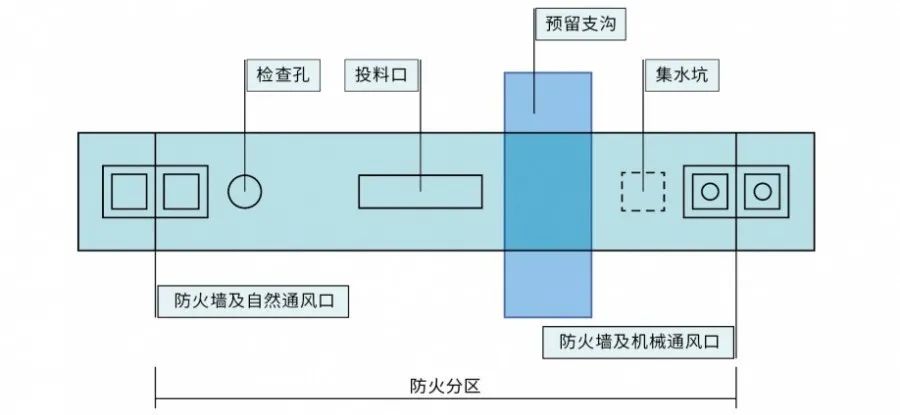

According to the requirements of the code, a safety escape hole for the personnel, a feeding port, a vent, a fire door and a personnel entrance and exit should be provided every 200 meters along the length of the pipe corridor.

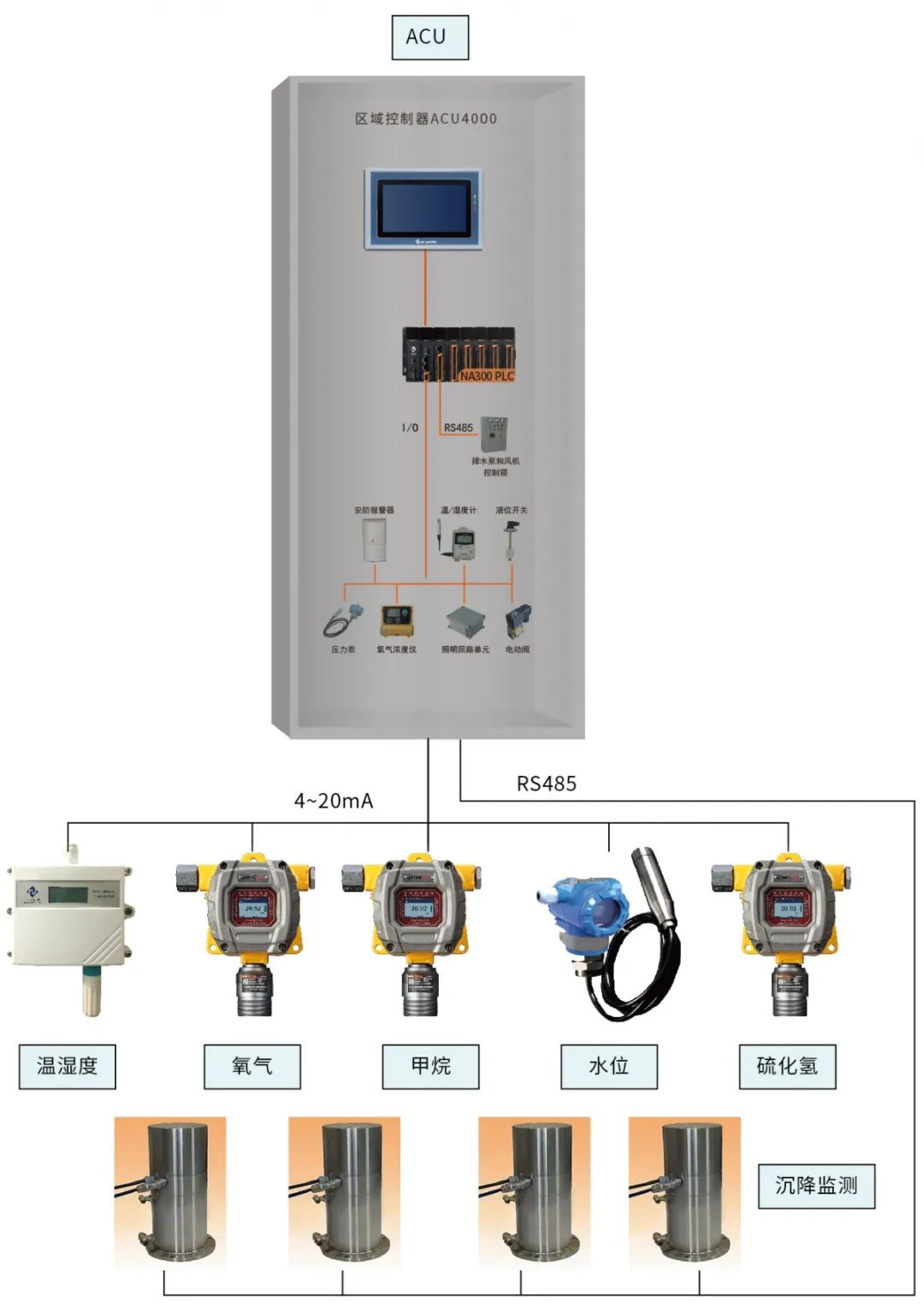

By installing monitoring sensors such as gas (O2, CH4, H2S), temperature, humidity, smoke, water level, and water immersion at the entrance and vent of each fire compartment, automatic control and docking with fans and pumps can be achieved. The detection signal is transmitted to the integrated management and control zone station nearby and sent to the monitoring center computer via Ethernet. On the display screen of the control room of the monitoring center, the gas (O2, CH4, H2S), temperature, humidity, smoke, water level and other data of each fire compartment are displayed in digital form.

According to the requirements of the "Technical Specification for Urban Municipal Comprehensive Pipe Corridor" as follows:

Each integrated pipe corridor fire partition is designed with an environmental monitoring system, including:

- 2 temperature and humidity sensors, 1 water level sensor, 2 oxygen sensors, 2 hydrogen sulfide sensors, 2 methane sensors, integrated display function.

- Temperature, humidity, oxygen, hydrogen sulfide, and methane sensors are installed near the sides of the fire door (close to the location of personnel access).

- The water level sensor is installed in the sump and integrates a local display device.

- 4 subsidence monitoring sensors provide standard modbusRTU interface.

The connection diagram of the environment and equipment monitoring subsystem is as follows:

Equipment monitoring >>>

Collect data on instruments and equipment such as drainage pumps, lighting, fans, air duct valves, infrared intrusion alarm devices, ambient temperature, humidity and oxygen detection instruments arranged in each fire compartment. Monitor the upper limit alarm signal of the water level in the water collection well. Transfer to the unified information management platform through the corresponding multi-functional integrated management and control zone station. At the same time, the multi-functional integrated management and control zone station accepts the command of the monitoring center to realize the remote control of the start and stop of the fan and the control of the lighting equipment in the corresponding fire zone.

The schematic diagram of the device monitoring connection is as follows:

ACU model and equipment configuration list >>>

Scan the QR code to read on your phone

底部二维码

Welcome to Atekon

Technology official Wechat

底部联系方式

Address: Floor8,BuildingD,Cloud Security City,No.19 Ning shuang Road,Yuhuatai District,Nanjing

Production Center: No. 219 Qingshuiting West Road, Jiangning District, Nanjing City

Telephone: 025-68530188 (Switchboard)

Fax: 025-68530178

Service Hotline: 400-025-0150

Technical support: 025-68530179

底部备案号

Atekon Technology Co.,Ltd Record number: 苏ICP备09042342号-1