Welcome to the offical website of Atekon Automation Technology Co.,Ltd

Solutions

Application Case of Disaster Prevention Safety Monitoring System of Nanda Automation Railway Tunnel

- Categories:Rail

- Author:

- Origin:

- Time of issue:2020-03-27 18:30

- Views:

(Summary description)The NA series programmable controller independently developed by Nanda Automation Technology Co., Ltd. is mainly used in railway tunnels, especially high-speed railway (including passenger-only railways, intercity railways) tunnel electromechanical equipment comprehensive monitoring and management system, mainly to complete the power facilities in the tunnel , Centralized monitoring, fault alarm and dispatch management of lighting/emergency lighting equipment, fans, water supply and drainage facilities, fire doors, etc.

Application Case of Disaster Prevention Safety Monitoring System of Nanda Automation Railway Tunnel

(Summary description)The NA series programmable controller independently developed by Nanda Automation Technology Co., Ltd. is mainly used in railway tunnels, especially high-speed railway (including passenger-only railways, intercity railways) tunnel electromechanical equipment comprehensive monitoring and management system, mainly to complete the power facilities in the tunnel , Centralized monitoring, fault alarm and dispatch management of lighting/emergency lighting equipment, fans, water supply and drainage facilities, fire doors, etc.

- Categories:Rail

- Author:

- Origin:

- Time of issue:2020-03-27 18:30

- Views:

The solution of NA-PLC railway tunnel disaster prevention and safety monitoring system

The NA series programmable controller independently developed by Nanda Automation Technology Co., Ltd. is mainly used for railway tunnels, especially high-speed railway (including passenger-only railways, intercity railways) tunnel electromechanical equipment comprehensive monitoring and management system, mainly to complete the power in the tunnel centralized monitoring, fault alarm and dispatch management of facilities, lighting/emergency lighting equipment, fans, water supply and drainage facilities, fire doors, etc.In the event of a disaster, it can be linked with FAS or other automated systems to automatically control according to the pre-generated disaster plan output , to achieve the purpose of disaster prevention and mitigation, to ensure the safe operation of the train.

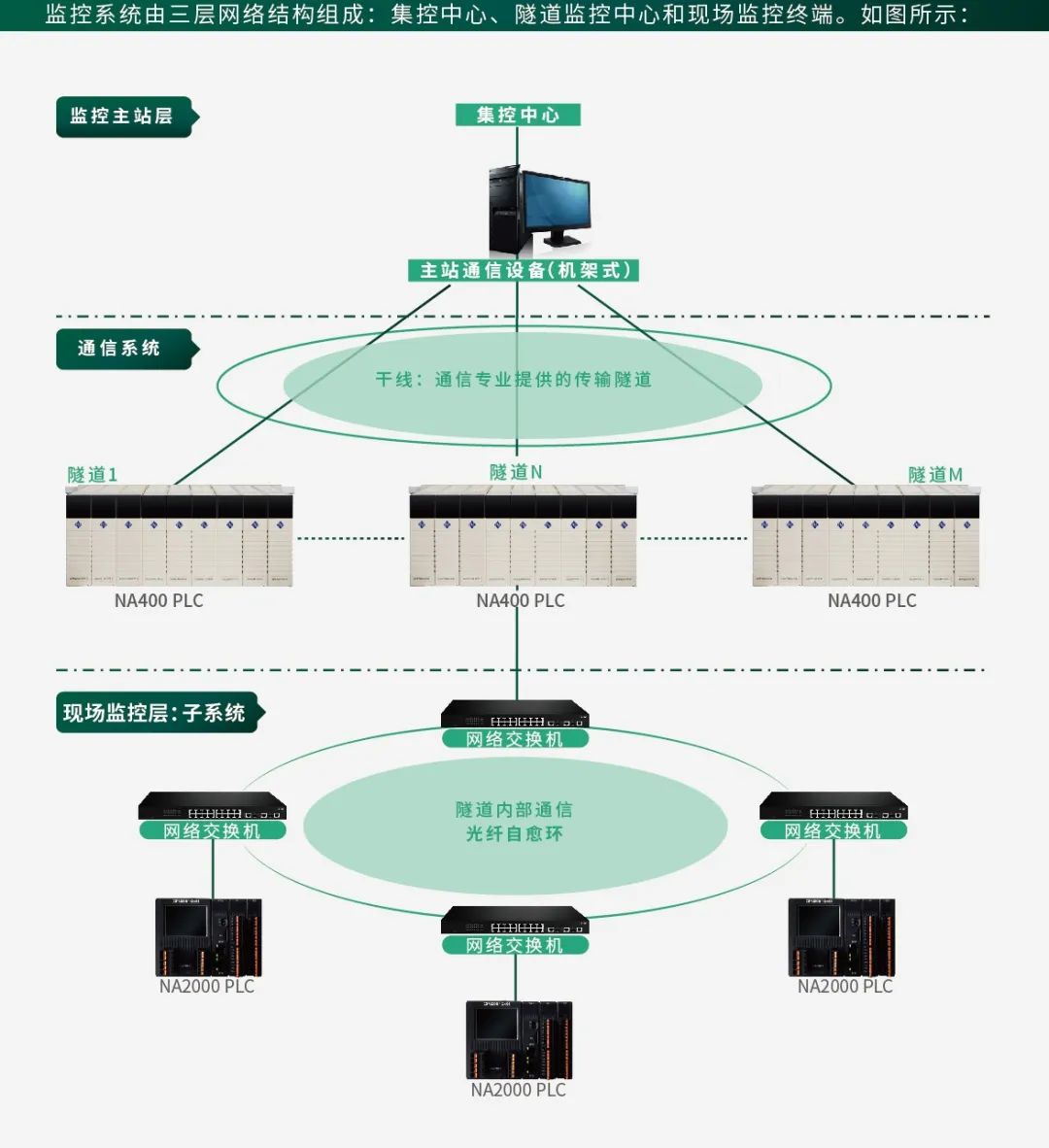

The products of Nanda Automation Technology Co., Ltd. mainly complete the data collection work of the tunnel monitoring center and on-site monitoring terminal. Among them, the tunnel monitoring center uses NA400 medium and large PLC to complete the hot standby redundant system solution, which can realize power supply redundancy CPU redundancy and Network redundancy to ensure the safety and reliability of data collection. The on-site monitoring terminal mainly adopts our company's NA2000 series integrated Ethernet interface small integrated controller, NA2000 system controller integrates Ethernet interface, multiple RS485 interfaces and rich I/O interfaces. The site's current level data collection and control work, Complete data exchange through the optical fiber ring network and NA400 PLC.

Application of NA-PLC in Disaster Prevention and Rescue Equipment Monitoring System of High-speed Railway Tunnel in Yunnan Section of Shanghai-Kunming

With the rapid development of railway construction in my country, railways are not only built in plains and hills, but also in mountainous areas and rivers and lakes with complex geological conditions. In order to optimize the direction of the line, shorten the length of the line, and overcome the unfavorable geological conditions, the Changda Mountain Tunnel and the underwater tunnel are increasingly showing their superiority in the railway line, but they also bring new problems in disaster prevention and evacuation. This time, the Nanda Automation NA series PLC was adopted as the core controller of the tunnel disaster prevention and rescue equipment monitoring system in the Yunnan section of Shanghai-Kunming and Yunnan section of Yunnan and Guizhou, which achieved good results in the field application.

System Overview >>>

The process of the monitoring system is that the road center sends commands to the main control through the MODBUS TCP protocol and monitors the status of field devices. The main control receives the command from the road center and forwards the commands to the remote station through the MODBUS TCP protocol. With the positive hole control, the main control of the fan control starts and stops the positive hole lighting and starts and stops the fan through the MODBUS TCP protocol. The remote station receives the main control instruction and starts and stops the rescue tunnel lighting and fan through MODBUS TCP protocol.

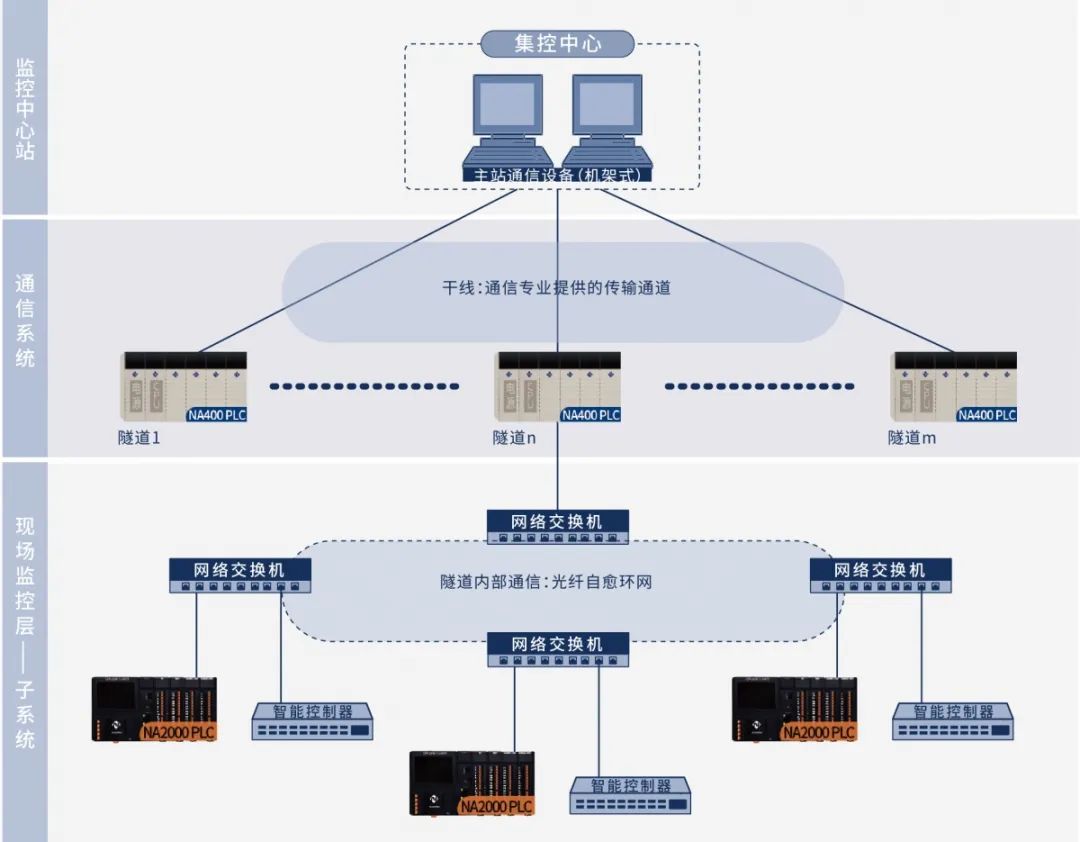

1. The monitoring system consists of three layers of network structure: centralized control center, tunnel monitoring center and on-site monitoring terminal.

2. Single rescue tunnel hardware architecture

NA-PLC products mainly complete the data collection work of the tunnel monitoring center and on-site monitoring terminal. Among them, the tunnel monitoring center uses the NA400 medium and large PLC to complete, and uses the hot standby redundant system solution to achieve power supply redundancy, CPU redundancyand network redundancy to ensure the safety and reliability of data collection. The on-site monitoring terminal mainly adopts the small integrated controller of NA200H series integrated Ethernet interface. The NA200H system controller integrates an Ethernet interface, multiple RS485 interfaces, and rich I/O interfaces. The site now has ground-level data collection and control work, and completes data exchange through the fiber optic ring network and NA400 PLC.

3. Monitoring system

The configuration screen of the system was developed by Sichuan Kuanggu Information Engineering Co., Ltd. The system screen is as follows:

4. Site environment diagram

This project is designed and implemented by Sichuan Kuanggu Information Engineering Co., Ltd. The product adopts NA-PLC

System function design >>>

The host computer uses the configuration software to compile the corresponding program to realize the monitoring and display of the field equipment. The system control methods are mainly automatic manual, automatic centralized control and manual operation.

①Automatic manual is to use the mouse to start\stop a single controllable device;

②Manual operation uses the button on the on-site control box to start\stop a single controllable device;

③Automatic centralized control is to start, run, stop and run the entire control system automatic operation and online monitoring of the entire process such as fault alarm and protection shutdown during the process.

NA400PLC software design

The software design of the program control system uses a ladder diagram, and adopts a modular design method to divide the functions that the entire control system needs to complete into several modules, and then design them separately. The advantage of this is that the design is convenient and it is easy to modify the program, making the procedure is clear and organized.

①Automatic centralized control function module design

②Automatic manual function module design

③Analog processing module design

④Communication module design with upper computer

⑤Alarm module design

Configuration software design

The configuration software is developed by Sichuan Kuanggu Information Engineering Co., Ltd., which mainly has the following parts.

①Monitoring screen making

②Parameter configuration screen making

③Alarm screen making

④Building database

⑤Real-time trend graph and historical trend graph

Scan the QR code to read on your phone

底部二维码

Welcome to Atekon

Technology official Wechat

底部联系方式

Address: Floor8,BuildingD,Cloud Security City,No.19 Ning shuang Road,Yuhuatai District,Nanjing

Production Center: No. 219 Qingshuiting West Road, Jiangning District, Nanjing City

Telephone: 025-68530188 (Switchboard)

Fax: 025-68530178

Service Hotline: 400-025-0150

Technical support: 025-68530179

底部备案号

Atekon Technology Co.,Ltd Record number: 苏ICP备09042342号-1