Welcome to the offical website of Atekon Automation Technology Co.,Ltd

Solutions

Solutions for automatic control system of urban sewage treatment plant

- Categories:Municipal

- Author:

- Origin:

- Time of issue:2020-04-07 08:41

- Views:

(Summary description)*** The first-stage construction of the fourth sewage treatment plant in the city has a treatment scale of 60,000 m3/d, a long-term treatment scale of 240,000 m3/d, and the main treatment process is A2/O. According to the technological requirements and current status of the sewage treatment system of Chenzhou No. 4 Wastewater Treatment Plant, an advanced automatic control (including monitoring) system is designed.

Solutions for automatic control system of urban sewage treatment plant

(Summary description)*** The first-stage construction of the fourth sewage treatment plant in the city has a treatment scale of 60,000 m3/d, a long-term treatment scale of 240,000 m3/d, and the main treatment process is A2/O. According to the technological requirements and current status of the sewage treatment system of Chenzhou No. 4 Wastewater Treatment Plant, an advanced automatic control (including monitoring) system is designed.

- Categories:Municipal

- Author:

- Origin:

- Time of issue:2020-04-07 08:41

- Views:

Project Description

*** The first-stage construction of the fourth sewage treatment plant in the city has a treatment scale of 60,000 m3/d, a long-term treatment scale of 240,000 m3/d, and the main treatment process is A2/O. According to the technological requirements and current status of the sewage treatment system of Chenzhou No. 4 Wastewater Treatment Plant, an advanced automatic control (including monitoring) system is designed. In accordance with the design concept of decentralized control, the equipment of each sub-station is controlled by the sub-station controller, and the data is sent to the central control room for comprehensive monitoring. Each control substation is reasonably arranged according to the nearest control principle, reducing the cost of I/O signal cables and their laying, reducing the repeated setting of equipment and operating personnel, and achieving the goals of reducing capital investment and reducing staff efficiency.

Process flow

System structure and composition

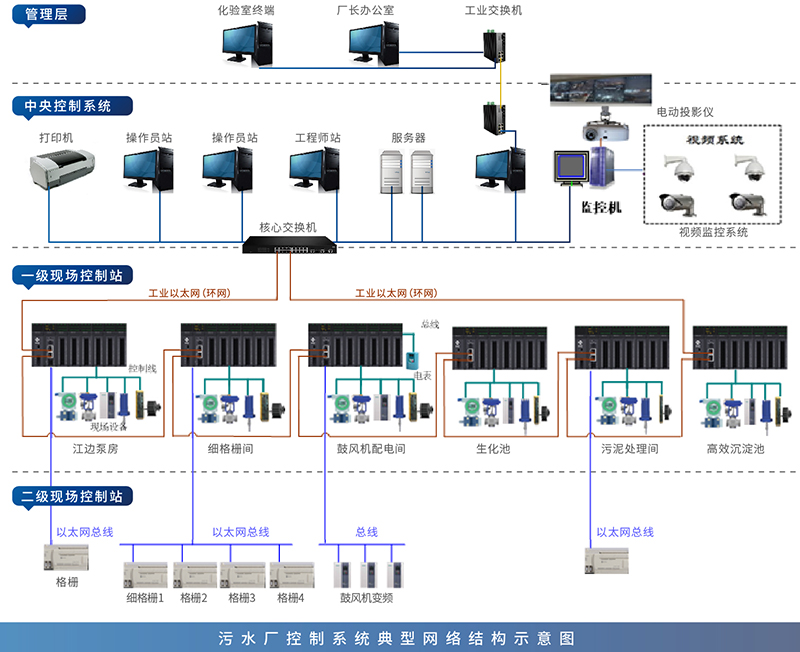

1. Network structure

The control system uses the NA300 series process controller as the hardware platform to provide a complete, highly reliable, and scalable collaborative automation control system for the project. According to the actual situation and technological requirements of the project, the system adopts a distributed system of "centralized monitoring, management and decentralized control". The central control center consists of servers, monitoring PC stations, printers, etc. The on-site control substation is composed of PLC and cabinet, touch screen, control power distribution system (including UPS) and industrial Ethernet switch. See the network structure diagram for details.

2. Controller

- Adopt Intel Pentium M processor, main frequency 300MHz, high performance CPU, high reliability.

- Comes with Ethernet interface, supports Modbus TCP and OPC protocol.

- 32M memory space + 32M storage space.

- Comes with a real-time clock, used to record the current time and time control of the process.

- With Watchdog function, it can automatically reset and restart in case of failure.

- Support hot swap.

- Data power-off protection.

System functions

Online monitoring of water quality indicators >>>

It can automatically detect the water quality indicators in the sewage treatment process by various on-line water quality analysis instruments, replacing the traditional sampling and laboratory analysis, so that the water quality can be monitored throughout the process.

Automatic control function >>>

The control system automatically controls the grid, biochemical tank, sedimentation tank, sludge treatment and other process equipment in the sewage treatment process, which further reduces the labor intensity of workers and realizes the automatic control of the entire process of the sewage plant.

Production process management >>>

Through the real-time monitoring of the production process through the computer system, the production process data collection, data storage, accident records, historical data query, report statistical printing and other management functions are realized, and the production management mode of the sewage treatment plant is further improved and perfected.

Energy saving >>>

Through advanced control strategies and information technology, the automation level and management level of the sewage plant have been improved, equipment maintenance costs have been reduced, energy consumption has been effectively reduced, production costs have been controlled, and the labor intensity of workers has been reduced.

Functions of the man-machine interface

Process flow chart display >>>

Really reflect the production process, the picture is simple and smooth, and the process flow produces a vivid image. Screen traction switching is flexible and easy to operate.

Report display and printing function>>>

The system historical data is stored in a standard database format, supporting dBASE VI, ACCESS, ODBC format, etc. The report supports the calculation and processing of data. It not only has basic processing capabilities such as average, maximum, and cumulative values, but also supports the calculation of devices by time zone. The report is flexible and can generate daily, monthly, quarterly, and annual reports according to user requirements. The report parameters can be manually corrected based on actual measured values.

Alarm function >>>

The alarm function reminds the operating personnel to immediately understand the operation status of the equipment related to the alarm parameters, and to handle it when necessary, which is an important measure to ensure continuous and stable operation of production. View the alarm list at any time, and can confirm the single alarm, full screen alarm and all alarms.

Real-time trend graph and historical trend graph >>>

Real-time trends can be directly obtained by right-clicking, and multiple trends can be displayed on the unified interface. The historical trend graph collection period is 10 seconds, and N collection points are displayed at the same time in the table, which is convenient for comparative analysis. The historical trend graph supports the function of displaying by system according to time period. The default storage time of the historical database is 2 years. , Supports saving and backup of database files. Powerful historical data automatic and historical event query function.

Operation authority management and operation record function >>>

Provide different operation login rights for visiting/browsing personnel, operating personnel, maintenance engineers, etc. It has operation record and operation event record function, and supports powerful data query function, and supports partition and sub-site query function according to time period.

Product configuration features

-

The system adopts domestic brand PLC products of independent brands.

-

For corrosive environments such as biochemical pools, the relevant hardware equipment is subject to three-proof treatment.

-

Following the principle of decentralized control, each sub-control station is equipped with a controller.

-

The product provides a universal standardized communication interface, supports PROFIBUS/HART/MODBUS/OPEN CAN and other common field buses, each control.

-

Using Ethernet architecture, high-speed communication, reserved bandwidth, standard TCP/IP protocol.

-

The PLC supports ring network connection itself, which enhances the stability of the network system and saves configuration costs.

-

The 100M industrial Ethernet self-healing ring network connection for fiber self-healing.

-

Good versatility and user-friendly design.

-

Strong after-sales service and technical support team.

Scan the QR code to read on your phone

底部二维码

Welcome to Atekon

Technology official Wechat

底部联系方式

Address: Floor8,BuildingD,Cloud Security City,No.19 Ning shuang Road,Yuhuatai District,Nanjing

Production Center: No. 219 Qingshuiting West Road, Jiangning District, Nanjing City

Telephone: 025-68530188 (Switchboard)

Fax: 025-68530178

Service Hotline: 400-025-0150

Technical support: 025-68530179

底部备案号

Atekon Technology Co.,Ltd Record number: 苏ICP备09042342号-1