Welcome to the offical website of Atekon Automation Technology Co.,Ltd

Product

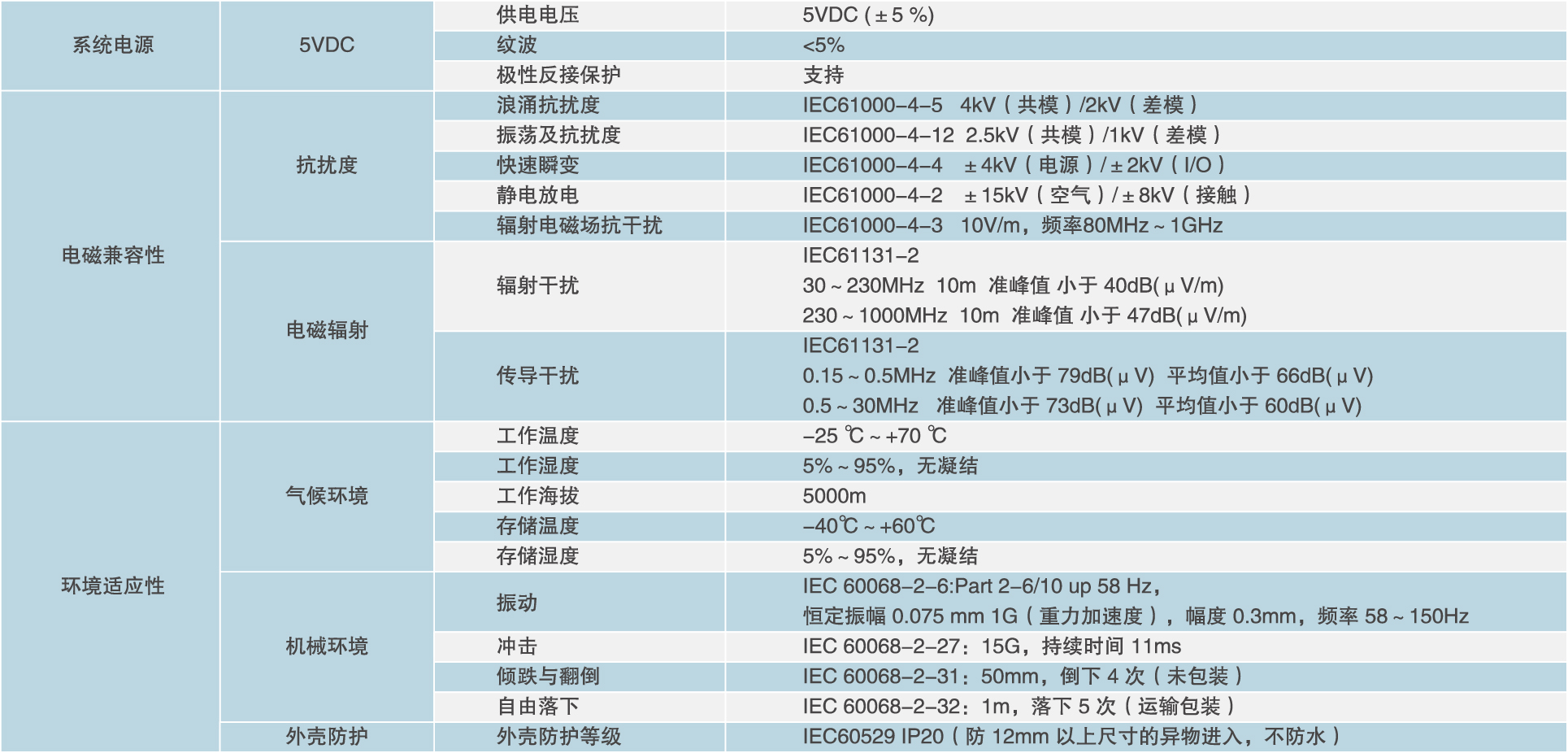

NA400 PLC hardware system general technical indicators

Far higher electromagnetic compatibility than other PLCs

The concept of electromagnetic compatibility runs through the entire development process from principle design, circuit board design to system structure design. Most of the EMC indicators exceed the level of the international standard level 3, and the static electricity and fast transients have reached the level of level 4.

Network programming and debugging

NA-PLC uses unified programming and debugging software. Provide 10/100M Ethernet as a programming and debugging interface, provide program download and online online debugging functions. Support remote programming and debugging through Ethernet to meet the modification and online maintenance of the control flow of local control devices in remote control centers.

Fieldbus technology

NA-PLC adopts field bus network, in addition to the characteristics of fast communication rate, strong anti-interference ability, low cost, simple structure, good real-time performance and so on. It also has good scalability, easy to achieve flexible configuration of the module, greatly improving the adaptability to the site environment and installation requirements.

Direct satellite synchronous clock interface

Directly connect the satellite clock signal of DC24V level to the connection terminal without maintenance. The event time scale is generated by the event sequence recording module, and the time is more accurate.

Sequential control chart programming technology

Sequential control chart programming language designed with "what you see is what you get" technology is a visual programming language, which is very suitable for complex sequential control processes, and it is very similar to the control process designed by the design unit. When the control flow design is completed, it means the end of programming, the programming process is simple and easy to learn. In addition, programs written in various languages can call each other, making program writing more flexible and convenient, and can meet the requirements of a variety of complex working conditions. Support sequential control chart configuration and operation, graphical display, single-step execution, locking and unlocking; through pre-compilation of sequential control chart to ensure correct execution of the program.

Powerful serial communication function

Serial communication module: The number of serial communication modules can be freely configured. Each serial communication module provides up to 4 serial ports. Each serial port supports the RS485 interface standard, supports the MODBUS RTU master-slave protocol, and all support the programmable mode.

*The information provided in this article is just a general description and feature introduction of the product.

*The content in the article may change with the further development of the product. The right of interpretation belongs to Nanda Automation Technology Co., Ltd.

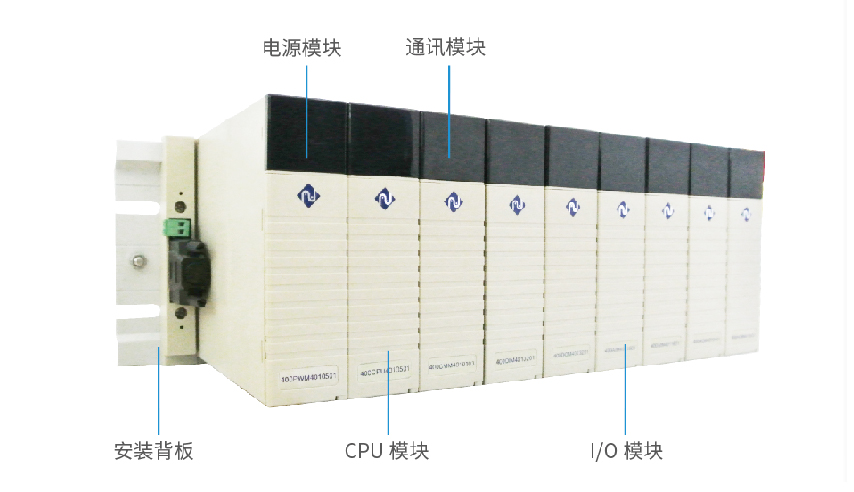

NA400 hardware system

Including the controller module, event sequence recording module, ordinary I/O module, communication processing module, backplane and system power supply, all modules are installed on the backplane.

Controller module

That is, the CPU module is installed on the local backplane, and there are two types of support for redundancy and non-redundancy. The controller has built-in 10/100Mbps Ethernet, dual serial port communication interface, and the internal bus is led out through the local backplane, which is convenient for hot plugging the controller.

SOE event sequence recording module

Provides SOE event sequence recording function with a resolution of 1ms.

Common I/O module

It can be installed on the local backplane and expansion backplane, and communicates with the controller through the high-speed internal bus.

Communication processing module

Can be installed on the local backplane and expansion backplane for adding other communication protocols. The NA400 controller can communicate with third-party devices through various network protocols such as RS232/RS485, DeviceNet, Profibus-DP, Ethernet, and CANopen. If the NA400 control system is required to provide a certain communication function, just install the corresponding communication module on the backplane. Various types of communication modules can support most mainstream network communication protocols.

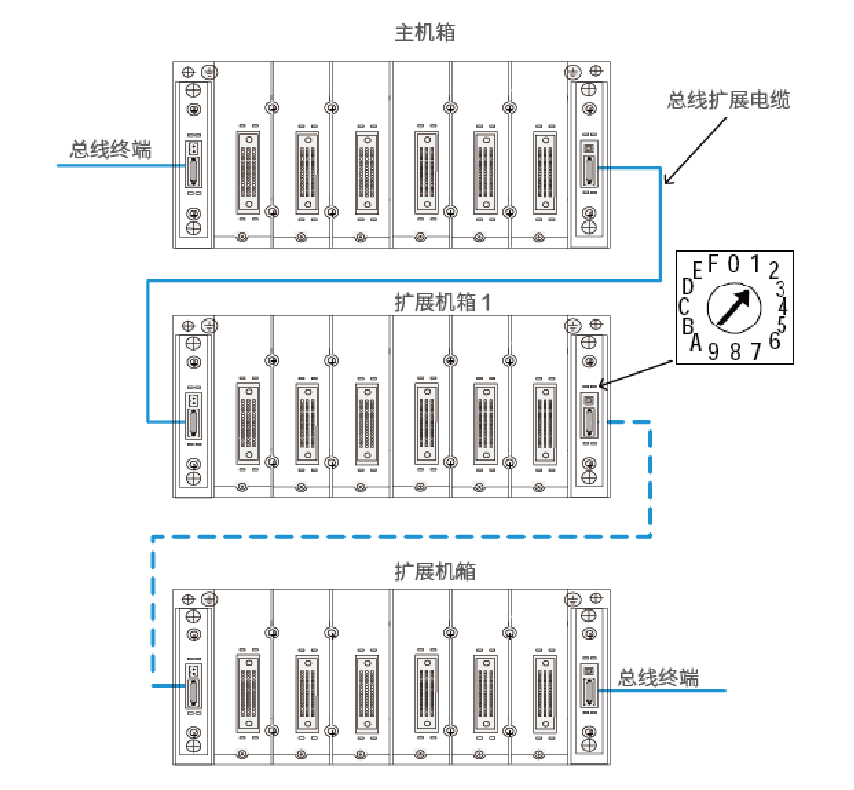

Backplane

Carriers for installing controllers, power modules, I/O modules, and communication modules, while supporting local high-speed bus expansion.

Power module

The power module is installed on the backplane to supply power to other modules; the power supply for the field equipment should be additionally configured to ensure the electrical isolation between the site and the system.

*The information provided in this article is just a general description and feature introduction of the product. The content in this article may change with the further development of the product, and the right of interpretation belongs to Nanda Automation Technology Co., Ltd.

底部二维码

Welcome to Atekon

Technology official Wechat

底部联系方式

Address: Floor8,BuildingD,Cloud Security City,No.19 Ning shuang Road,Yuhuatai District,Nanjing

Production Center: No. 219 Qingshuiting West Road, Jiangning District, Nanjing City

Telephone: 025-68530188 (Switchboard)

Fax: 025-68530178

Service Hotline: 400-025-0150

Technical support: 025-68530179

底部备案号

Atekon Technology Co.,Ltd Record number: 苏ICP备09042342号-1