Welcome to the offical website of Atekon Automation Technology Co.,Ltd

Solutions

The computer monitoring system of Yunnan Dali Liuhe Hydropower Station is put into operation with NA400 PLC

- Categories:Hydropower

- Author:

- Origin:

- Time of issue:2020-03-27 16:04

- Views:

(Summary description)

The computer monitoring system of Yunnan Dali Liuhe Hydropower Station is put into operation with NA400 PLC

(Summary description)

- Categories:Hydropower

- Author:

- Origin:

- Time of issue:2020-03-27 16:04

- Views:

Project Overview: The Heqing County Liuhe Hydropower Project is located in the canyon section of the lower Yangtze River near Changwei Village, Liuhe Township, southeast of Heqing County. The power station is the fourth-level power station among the first-level and six-level power stations planned and constructed in the Shimenkan to Hekou section of the lower Yangtze River valley. Power generation is mainly concentrated in June to October. It belongs to a seasonal power station using seasonal resources and is a runoff power station. Two generators are installed with an installed capacity of 2×15000W, a design head of 235m, a designed power generation flow of 14.48 m3/s, an annual power generation of 148 million kW·h, and a diversion tunnel length of 5,933.285m.

This computer monitoring system uses NA400 PLC, NA400PLC provides professional SOE event recording module, time accuracy is less than 1ms. It provides self-programmable serial communication module CMM401-0411, 4 RS485 interfaces. Each set of CPU can expand 4 modules, up to 16 serial ports, to meet the requirements of power plant automation communication interface.

Nanda Automation Technology Co., Ltd. has rich application performance in hydropower stations, has decades of industry application experience accumulation, and a rich PLC product series. The following is the photo sent by the customer from the scene:

Figure 1 Exterior of Liuhe Hydropower Station in Dali, Yunnan

Figure 2 Inside the Dali Liuhe Hydropower Station in Yunnan

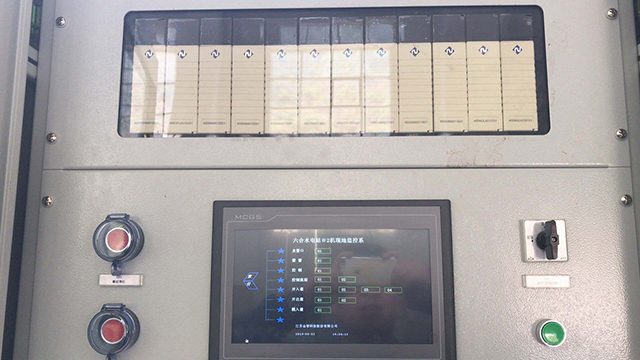

Figure 3 Liuhe Hydropower Station #2 machine local monitoring system

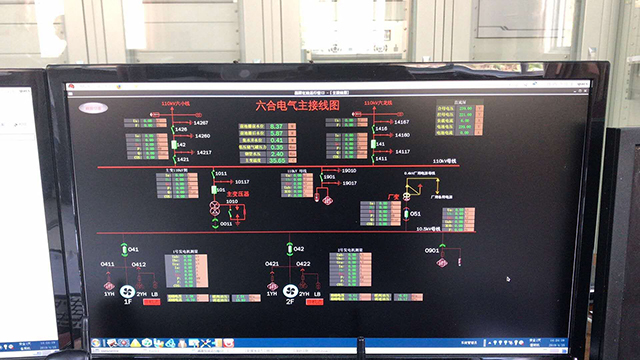

Figure 4 Main wiring diagram of Liuhe Electric

1. A variety of CPUs provide factory-wide automation solutions

NA400PLC provides a variety of CPU models from economical to hot standby redundant, which can meet the requirements of unit monitoring system for medium and large hydropower stations.

Figure 5 CPU401-0501 hot standby redundant CPU

2. Integrated RS485 multi-serial communication module

① Complete the communication protocol independently, that is, it can exchange data with NA400 CPU through CAN network, or exchange data with external serial devices through the serial port.

② 4 extended RS485 serial ports, which can support internal Modbus master station communication, and can also carry out custom protocol communication, and can communicate with debugging, excitation, and computer protection.

③ An RJ45 Ethernet interface, with NAComm software can be configured to monitor and debug.

④ Divide the input and output, which supports a maximum of 1024 switching input, 1024 switching output, 512 analog input, 512 analog output.

Figure 6 4RS485 serial communication module

Figure 7 Communication module extension cable

3. Professional SOE event recording module

The SOE event recording module directly receives GPS second pulse signal timing, and the time is more accurate. Simultaneously synchronize the time with the CPU. The SOE event is generated by the event recording module and transmitted to the CPU through communication. The internal memory of the module can record up to 2048 events to prevent time loss after communication with the CPU is interrupted.

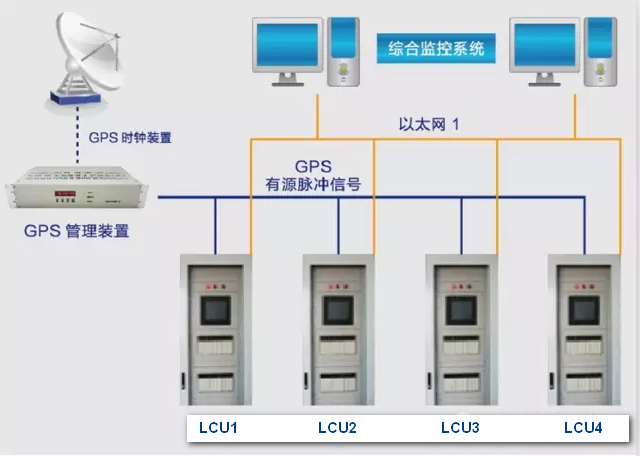

4. Professional satellite timing network

NA400 PLC supports multiple timing methods such as NTP, B code, etc. At the same time, it supports PPM sub-pulse timing to ensure that the SOE time accuracy error of the entire system is less than 1ms.

图8 GPS对时网络

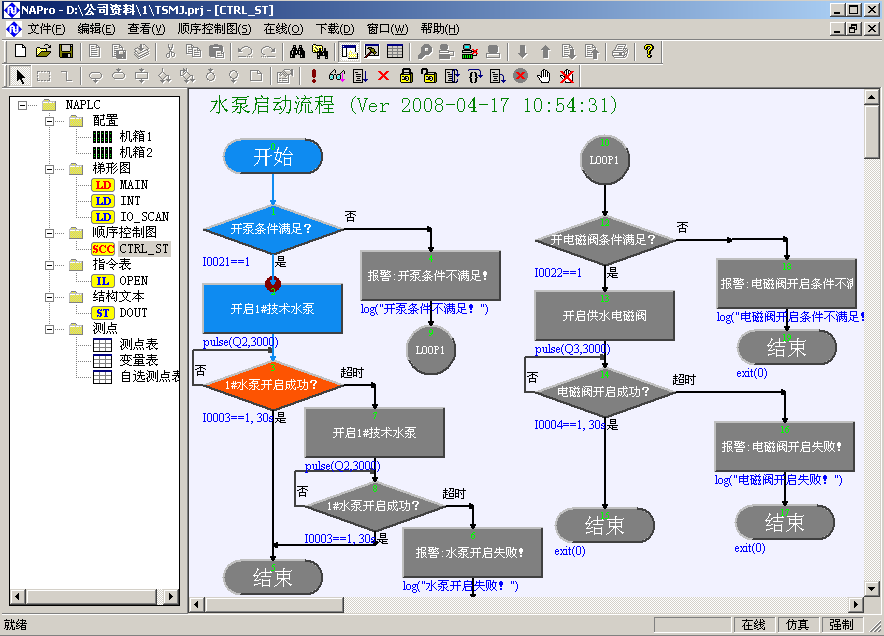

5. Intuitive flow chart editing language

Our company has developed a sequential control programming language for the characteristics of sequential control of hydropower stations. It has fast programming, convenient modification, and intuitive debugging, which greatly shortens the programming time of field service personnel.

Figure 9 Sequential control chart programming interface

PLC runs stably and reliably on site, and has won unanimous praise from the owner and system integration manufacturers! ! ! Thank you for the photos from the scene!

Scan the QR code to read on your phone

底部二维码

Welcome to Atekon

Technology official Wechat

底部联系方式

Address: Floor8,BuildingD,Cloud Security City,No.19 Ning shuang Road,Yuhuatai District,Nanjing

Production Center: No. 219 Qingshuiting West Road, Jiangning District, Nanjing City

Telephone: 025-68530188 (Switchboard)

Fax: 025-68530178

Service Hotline: 400-025-0150

Technical support: 025-68530179

底部备案号

Atekon Technology Co.,Ltd Record number: 苏ICP备09042342号-1