Welcome to the offical website of Atekon Automation Technology Co.,Ltd

Solutions

Application of NA200 in refrigeration equipment of chiller

- Categories:Comprehensive case

- Author:

- Origin:

- Time of issue:2020-04-07 09:20

- Views:

(Summary description)A chiller is a refrigeration equipment that provides chilled water. It is widely used in the central air-conditioning system of large and medium-sized buildings such as hotels, office buildings, hospitals, shopping malls, etc., and the process areas where industrial departments such as metallurgy, petrochemicals, machinery, medicine and electronics require chilled water.

Application of NA200 in refrigeration equipment of chiller

(Summary description)A chiller is a refrigeration equipment that provides chilled water. It is widely used in the central air-conditioning system of large and medium-sized buildings such as hotels, office buildings, hospitals, shopping malls, etc., and the process areas where industrial departments such as metallurgy, petrochemicals, machinery, medicine and electronics require chilled water.

- Categories:Comprehensive case

- Author:

- Origin:

- Time of issue:2020-04-07 09:20

- Views:

A chiller is a refrigeration equipment that provides chilled water. It is suitable for the occasions where the central air conditioning system and industrial process need chilled water. It is widely used in the central air-conditioning system of large and medium-sized buildings such as hotels, office buildings, hospitals, shopping malls, etc., and the process areas where industrial departments such as metallurgy, petrochemicals, machinery, medicine and electronics require chilled water. The device uses NA200 PLC as the control core. The PLC outputs control signals to each actuator to control the operation of the unit. At the same time, PLC accepts the input signal of the unit, and responds to the work changes or abnormalities in the operation of each unit in a timely manner. The user controls the operation of the unit by operating the touch screen, and inquires about the operation of the unit.

System Configuration

1. Function introduction

(1). Automatic operation function:When the unit is set for automatic dehumidification operation, the control system determines the energy level to be put into operation by comparing the actual temperature and humidity of the current room with the set value to achieve the purpose of automatically controlling the supply air humidity.

(2). Debugging and running function:The commissioning operation is used to manually control the unit operation during unit commissioning. The actions of each unit can be directly controlled by the panel. This feature is not recommended for users.

(3). Power-off retention function:The power supply is re-powered after the power is cut off, and the control system can automatically restore the working state before the power cut.

(4). Password protection function:The control system sets a password protection function on important working parameters and debugging operation functions to prevent system disturbance caused by unrelated personnel modifying parameters.

(5). Fault self-diagnosis and processing functions:The control system checks the faults that occur during the operation of the unit at any time, handles the faults in time, and displays and records the fault type and the location of the fault. The control system also provides a pair of fault alarm output contacts for users to use.

(6). Query function:Using the query function, users can keep track of the operation status of the unit at any time. The control system displays the temperature and humidity of the supply air and the working status of the unit on the panel, and can query the cumulative running time of the unit, control parameters and unit fault conditions.

(7). Remote control function:The operation panel of the control system can be installed far away from the unit at the location required by the user to achieve comprehensive remote control operation. (Users who want to use this function must ask when ordering, the distance should not exceed one kilometer.)

(8). Remote monitoring function:Using the host computer and modem to connect through the public telephone line can realize the remote monitoring unit operation function. (Users who want to use this function must ask when ordering, and the distance is unlimited.)

(9). External interface:PLC with RS232 and RS485 interfaces can be connected to the centralized monitoring system of the intelligent building.

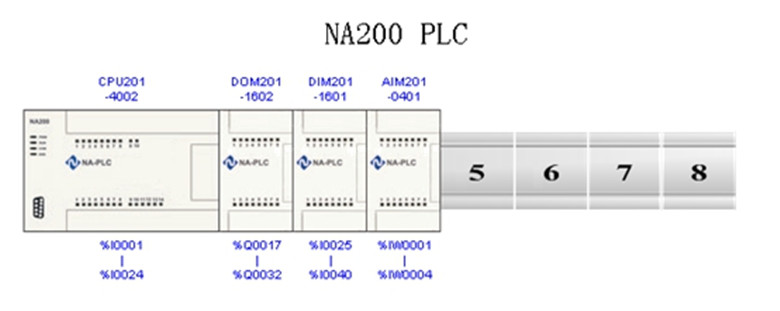

2. PLC configuration

This set of chiller equipment selects Nanda Automation NA200 series PLC and its expansion module as the control core. The PLC configuration is shown below.

Figure 1 PLC module configuration

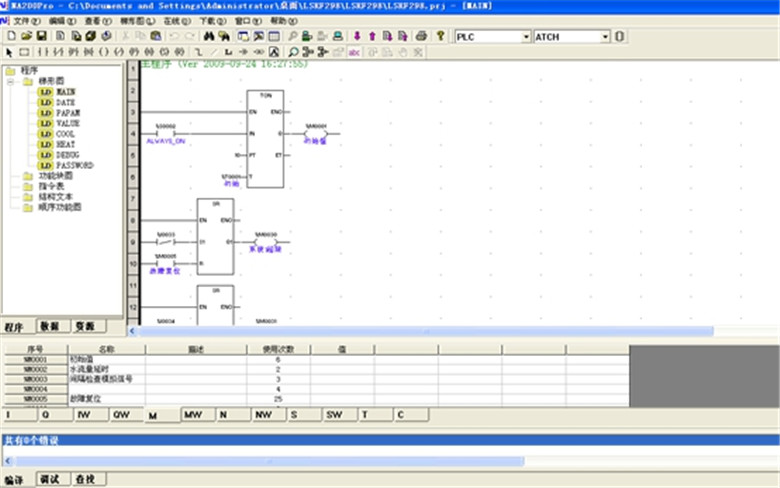

Figure 2 PLC program

Figure 3 touch screen picture

Scan the QR code to read on your phone

底部二维码

Welcome to Atekon

Technology official Wechat

底部联系方式

Address: Floor8,BuildingD,Cloud Security City,No.19 Ning shuang Road,Yuhuatai District,Nanjing

Production Center: No. 219 Qingshuiting West Road, Jiangning District, Nanjing City

Telephone: 025-68530188 (Switchboard)

Fax: 025-68530178

Service Hotline: 400-025-0150

Technical support: 025-68530179

底部备案号

Atekon Technology Co.,Ltd Record number: 苏ICP备09042342号-1